MIX-IND® PILOTA

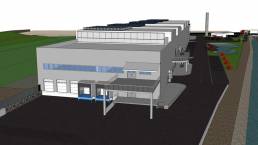

On the occasion of its 25th anniversary (1995–2020), SINTRA has established a new RESEARCH AND PRODUCTION CENTER called: MIX-IND® Pilot.

The MIX-IND® Pilot project is a production unit housed in a highly innovative facility, designed and equipped for the continuous research and development of advanced air treatment systems, specifically applied to large-volume buildings.

It will not only meet our production needs but will primarily serve as a center for continuous research and experimentation aimed at developing Next-Generation Systems.

The MIX-IND® Pilot will also represent a tangible example of integrated design, capable of combining innovation, technology, and productivity without waste—while ensuring maximum energy efficiency and optimal workplace comfort.

A High-Performance Building

Particular attention will be given to the development of new technologies aimed at addressing issues related to cold air infiltration from industrial doors and loading docks.

Unique in its kind, the MIX-IND® Pilot will also be a "high-performance building", demonstrating that the application of these new technologies enables the optimization of integrated building-system design without necessarily increasing the initial investment.

Innovative Structure

Structure with alternating-height spans

Acoustic Insulation

Roof Acoustic Insulation

Openable Windows

Operable windows with outdoor air filtration

Solar Heat Recovery

Passive Winter Solar Gain

Sun Shading Systems

Summer Solar Protection of Window Openings

Energy Efficiency

High-Energy-Efficiency Loading Docks

1. Impianto di riscaldamento con AUTOPULSER a lunga gittata (150m)

2. PULSORE® con angolo di lancio variabile motorizzato (VARIPULSE®)

3. TRAVE DI PULSIONE tipo TWIN-2 con tecnologia VARIPLENUM® (dimostrativa).

4. Impianto BIMODULAIR di superventilazione estiva per il desurriscaldamento estivo da 2.000.000 m3/h (50 vol/h) funzionante ad energia solare.

5. Impianto AUTOPULSER di pressurizzazione invernale con aria esterna non riscaldata.

6. Impianto BIMODULAIR® di free-cooling invernale estremo (680.000 m3/h).

7. Impianto sperimentale a pulsione radiale.

8. Colonne pressometriche per il controllo del livello di pressurizzazione dell’ambiente.

9. Impianto AUTOPULSER di rapida messa a regime per le banchine di carico.

10. TRAVE DI PULSIONE di tipo TWIN-2 per la sala ristoro.

11. ANELLO COLLETTORE COMPENSATO per la sala formazione.

12. Barriere esterne ad aria fredda VARIWIND® in diverse tipologie applicative.

Our Mission

Our mission in the market is to remain a leading company at the forefront of designing innovative systems for reducing energy consumption, with a sense of social responsibility to contribute—within our means—to greater environmental sustainability for the future of the next generations.

Discover the Latest News

Want to discover all the latest news from the Sintra world? Visit our blog!